Sandwich Rock wool Panel

Price 1000.0 INR/ Piece

MOQ : 1000 Pieces

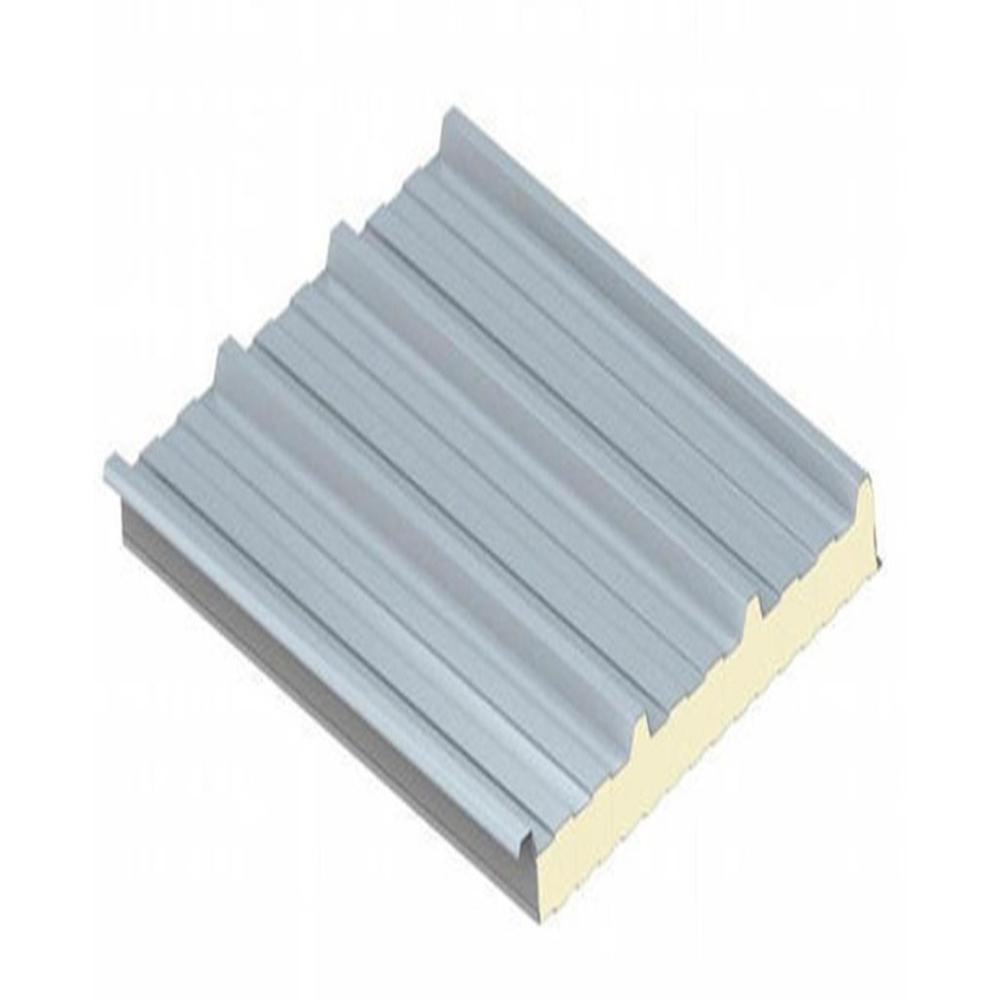

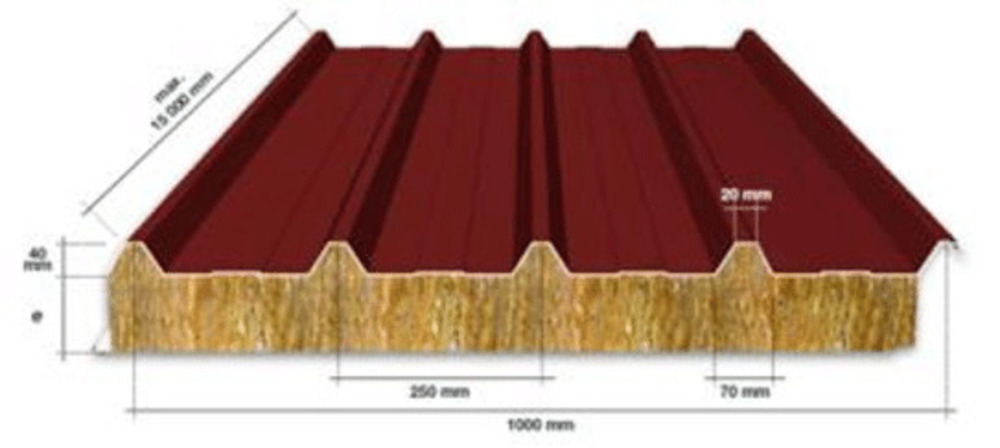

Sandwich Rock wool Panel Specification

- Surface Treatment

- Smooth

- Size

- Standard

- Warranty

- 1 year

- Display Type

- Nil

- Features

- Good Quality

Sandwich Rock wool Panel Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Delivery Time

- 5-10 Days

About Sandwich Rock wool Panel

- Rockwool insulation panel is able to withstand incredibly high temperatures, due to the fact that it is made from rock. In fact, it can handle 1000C without melting. Significant effect on reducing noise transmission. It contains 70% recycled material, making it a greener product.

Superior Insulation Performance

Sandwich Rock Wool Panels excel in providing both thermal and acoustic insulation, creating comfortable environments for commercial and industrial spaces. Their durable core and smooth surface further enhance their applicability in diverse climates and settings across India.

Manufactured with Quality Assurance

Produced by a reputable exporter and manufacturer in India, these panels undergo strict quality control to maintain consistency in size and surface treatment. The product is backed by a 1-year warranty, offering peace of mind and reliable long-term performance.

FAQs of Sandwich Rock wool Panel:

Q: How is the Sandwich Rock Wool Panel installed in construction projects?

A: The Sandwich Rock Wool Panel is typically installed using mechanical fasteners or adhesive systems onto steel or concrete frameworks in walls, partitions, or roofs. Professional installation ensures optimal insulation and secure fitting.Q: What benefits does the Sandwich Rock Wool Panel offer over conventional building materials?

A: This panel provides excellent thermal and sound insulation, fire resistance, and energy efficiency. The smooth surface treatment enhances durability and makes maintenance easier compared to traditional insulation products.Q: When should one consider using Sandwich Rock Wool Panels in a building project?

A: These panels are ideal during both new constructions and retrofitting projects that demand enhanced insulation, fire safety, and thermal performance, particularly in commercial and industrial facilities.Q: Where can the Sandwich Rock Wool Panel be used effectively?

A: The panels are perfect for wall and roofing applications in factories, warehouses, offices, and industrial complexes where insulation and fire proofing are required.Q: What is the manufacturing process involved for these panels?

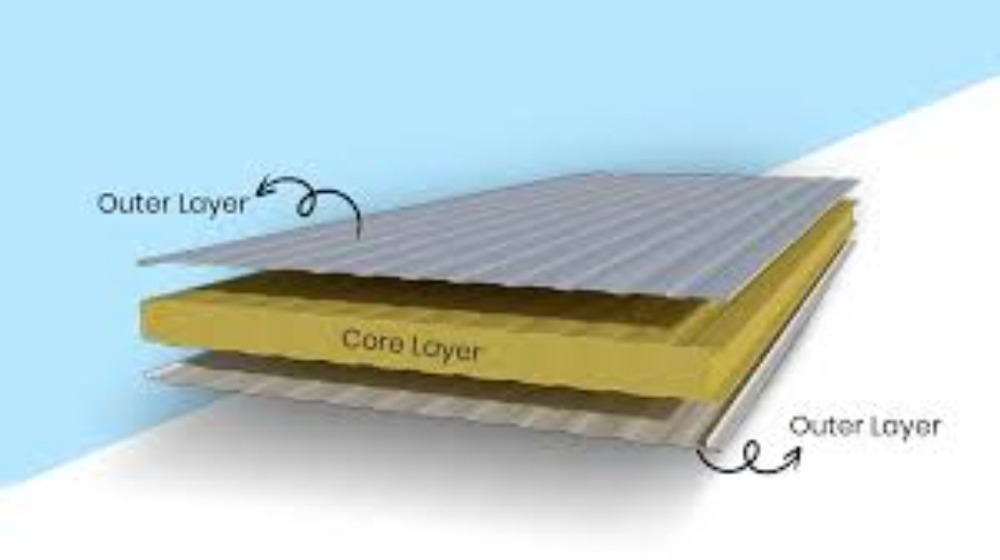

A: The panels are produced by sandwiching high-density rock wool between two metal sheets, followed by surface smoothing and quality checks to ensure uniformity, strength, and good insulation properties.Q: How does the 1-year warranty benefit the end user?

A: The one-year warranty covers manufacturing defects, giving customers added confidence in product reliability and manufacturer support for their investment.Q: What are the recommended usage guidelines for maximizing the panels effectiveness?

A: For best results, ensure installation is done by trained professionals. Use the panels in areas requiring insulation, follow standard maintenance, and avoid exposing them to excessive moisture beyond intended specifications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Roof Panel Category

Sandwich Puf Panel

Price 1000.0 INR / Piece

Minimum Order Quantity : 998 Pieces

Color : White

Material : Polyurethane Foam

Thickness : 40150 mm Millimeter (mm)

Width : 1000 mM Millimeter (mm)

Puf Panel

Price 1000.0 INR

Minimum Order Quantity : 5000

Color : Grey, Blue, Red,

Material : Puf Panel

Thickness : 30MM 150mm Millimeter (mm)

Width : 1000MM Millimeter (mm)

Send Inquiry

Send Inquiry